Sveaverken Nimbo X Feed Pusher

The smart feed pushing robot powered by 3D vision

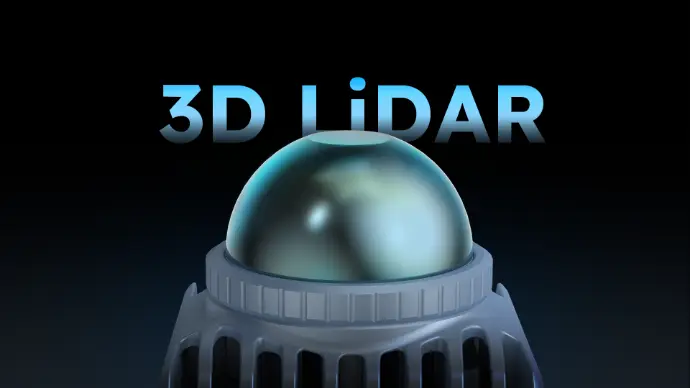

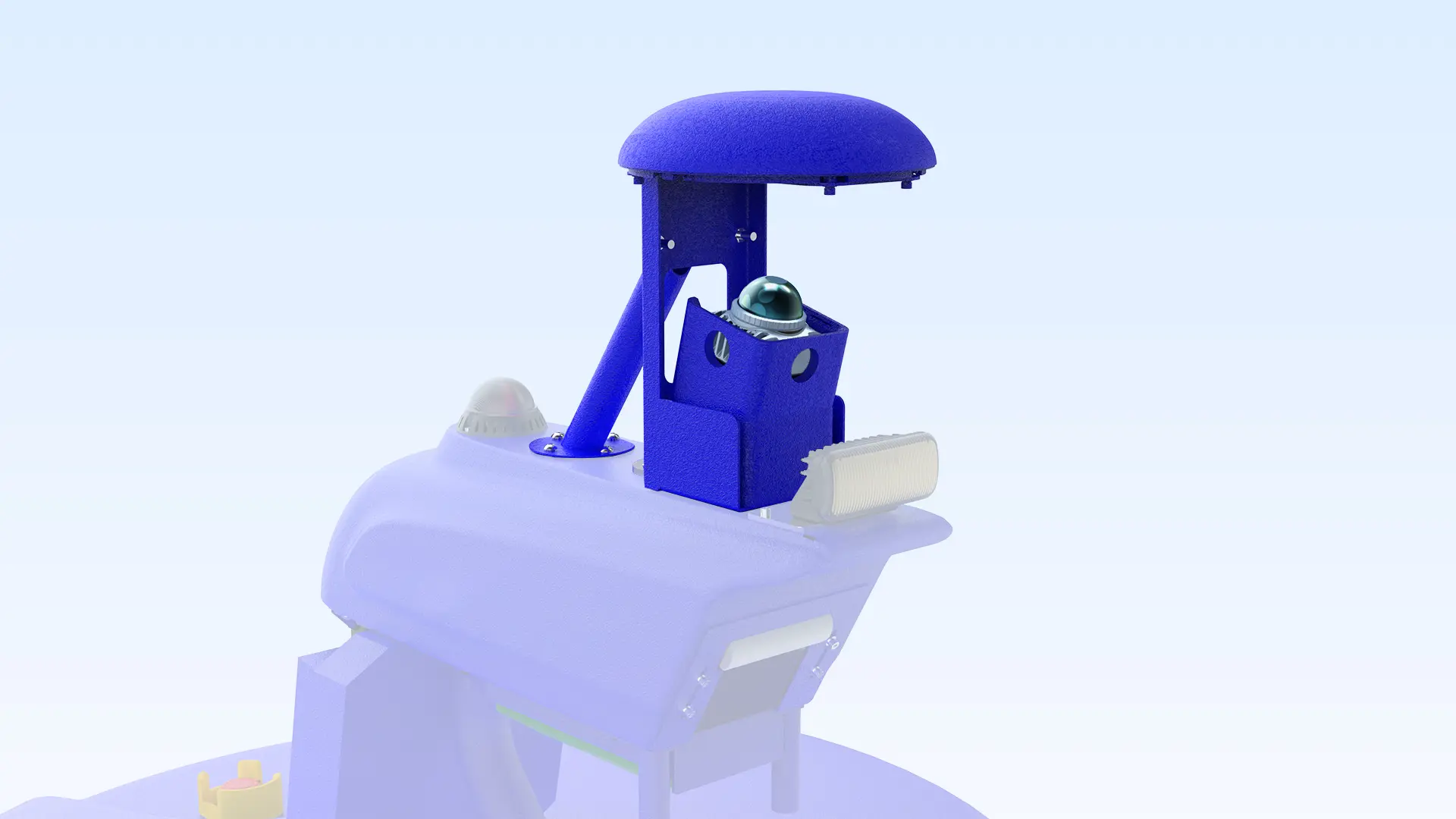

3D LiDAR

Maps your barn in full 3D

LiDAR PROTECTIVE COVER

Shields the sensor from dust and moisture

PHOTOSENSITIVE PLATE

Maintains stable performance in all lighting conditions

CAMERA SYSTEM

Supports obstacle detection and remote control

CLEANING BRUSH

Keeps the LiDAR sensor clear

CHARGING STATION

A

space-saving station for rapid deployment

ROLLER & RUBBER STRIP

Ensures smooth feed pushing

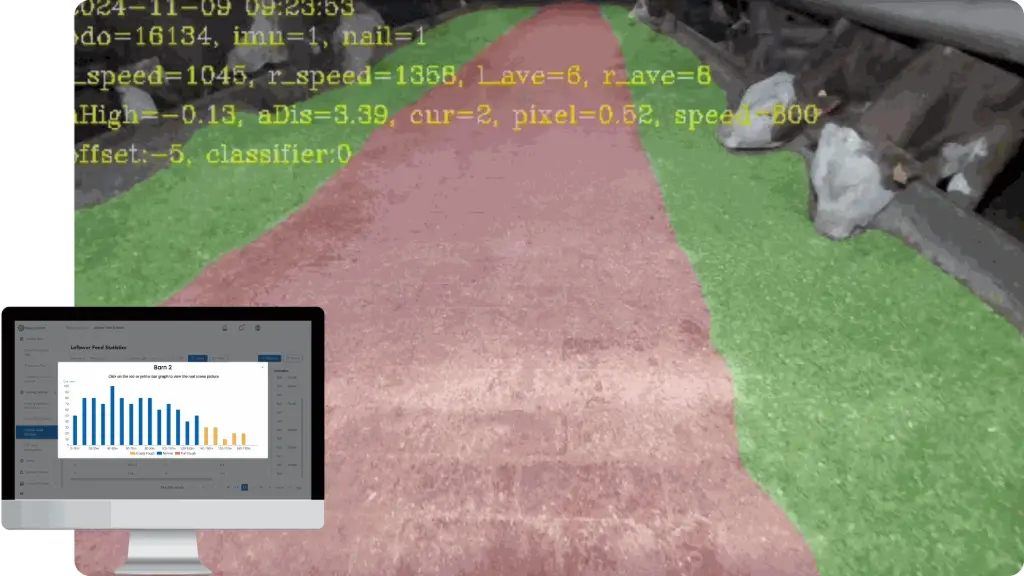

Precision Redefined with 3D LiDAR.

A self-driving robot feed pusher on your farm. Just like autonomous vehicles use LiDAR to navigate roads, the Nimbo X feed pusher uses advanced 3D LiDAR to navigate barns with centimeter-level accuracy — ensuring flawless robotic feed pushing with zero manual effort.

Pinpoint accuracy.

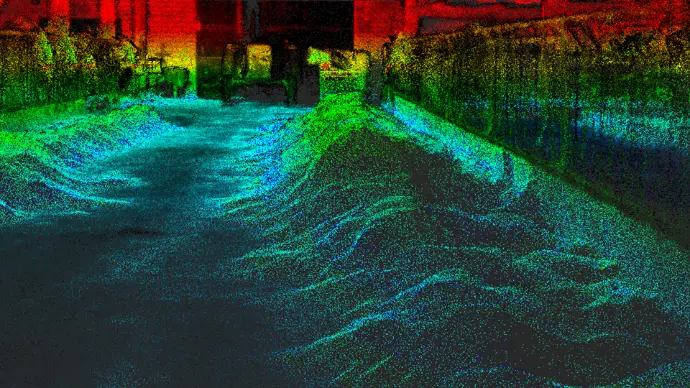

The Nimbo X uses high-frequency LiDAR scanning — 200,000 laser pulses per second — to build an ultra-precise 3D map of your barn. This pinpoint accuracy supports better task planning, real-time navigation, and smoother operation overall.

Maximum efficiency, minimal effort.

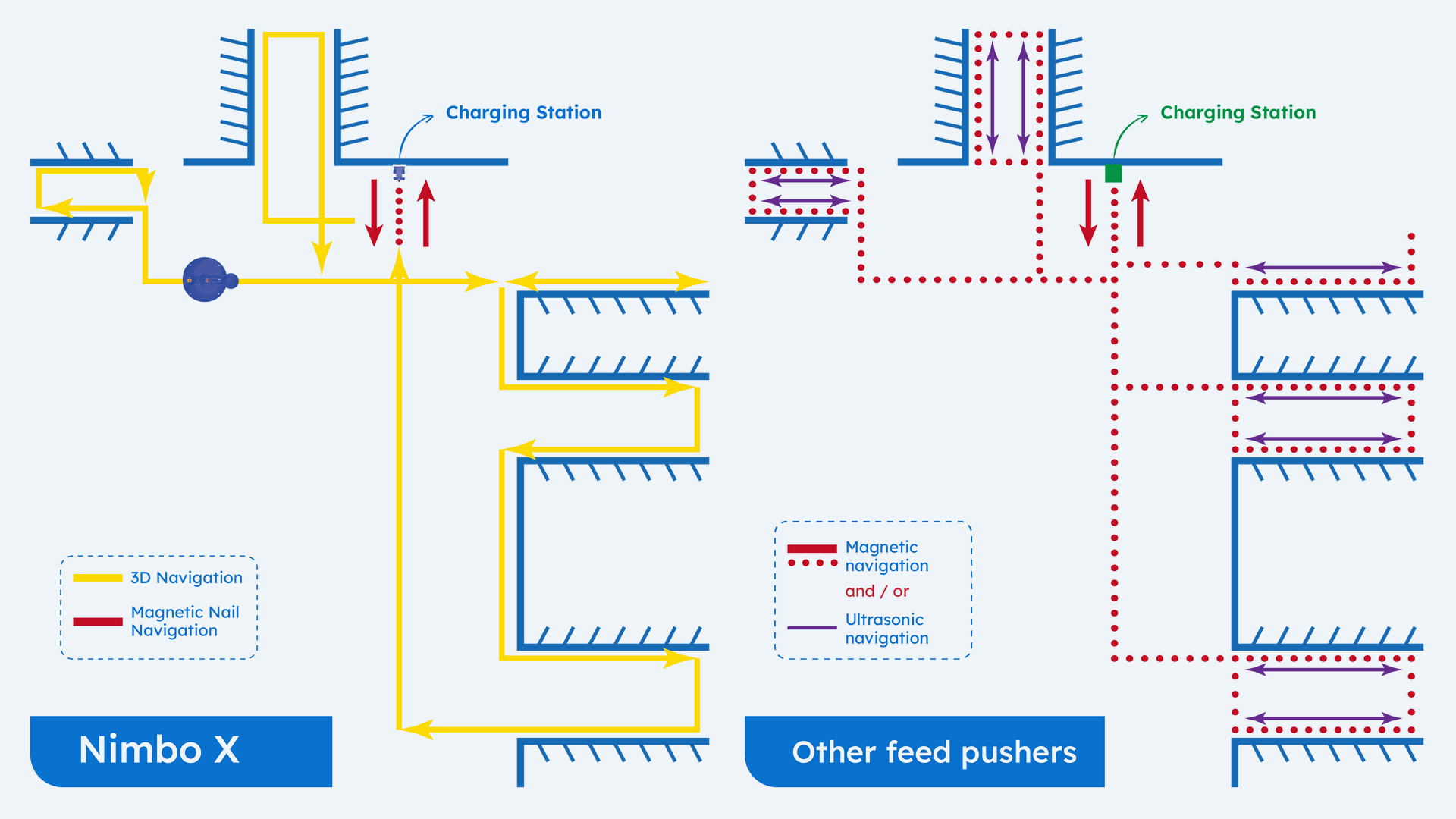

Unlike other feed pushers that rely on long magnetic strips, Nimbo X only needs a short 3-meter magnetic path from the charging station. That means faster installation, less disruption, and minimal setup time.

The quickest, easiest, and most affordable installation.

No more endless hours spent installing magnetic tracks. Just map your farm using a 3D scanner and let the Nimbo X feed pusher take it from there.

With 3D scanning, it's never been this simple.

Hold the laser scanner, walk through the barn, and let the tech do the rest. It automatically creates a 3D model, capturing walls, feed tables, and obstacles in just minutes. No manual measurements. No errors!

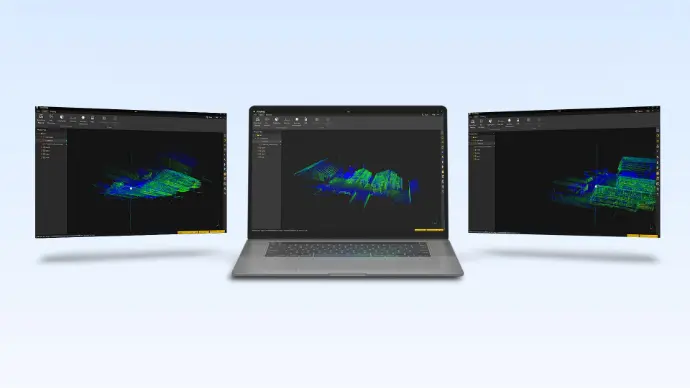

With SveaMap, it's never been this smart.

Upload your 3D model into SveaMap, our easy-to-use feed pusher mapping tool. With just a few clicks, you can design precise route for Nimbo X tailored to your farm layout — simplifying deployment and enhancing long-term robot performance.

Now comes the magic on the farm.

Once Nimbo X is deployed, its built-in 3D LiDAR and camera system continuously scan the environment in real-time. Using real-time data and custom maps, the robot feed pusher navigates smoothly and follows the exact path you designed with incredible accuracy.

Game-changing flexibility.

From narrow alleys to large barns, Nimbo X adapts to a wide range of farm sizes and layouts. It performs reliably in both daylight and low-light conditions, handling tough barn environments with ease.

Low maintenance.

With a self-cleaning LiDAR sensor and smart components, Nimbo X keeps itself in top condition. It’s one of the most hassle-free robotic feed pusher systems available today.

Stay informed with remote control & monitoring.

Through built-in cameras and Wi-Fi, you can control and monitor your Nimbo X remotely. View live footage, adjust paths, and push updates anytime from the MooConnect app — whether you’re in the barn or miles away.

A new level of safety.

Safety is core to the Nimbo X experience. Dual-layer protection — 3D LiDAR and AI-powered cameras — lets the robot detect obstacles in real-time. When something is in the way, it stops. When the coast is clear, it resumes work.

Always on, 100% automatic.

This smart feed pushing robot is designed to run around the clock. Its powerful lithium battery consumes less than 5% of its charge per task and can handle two days of operation on one charge, recharging automatically after each task to stay ready for the next one.

Steep slopes? Nimbo X Plus has you covered.

Need more power on rough terrain? Nimbo X Plus can lift its skirt and climb slopes up to 27%, delivering consistent feed pushing even on uneven barn floors and hilly layouts.

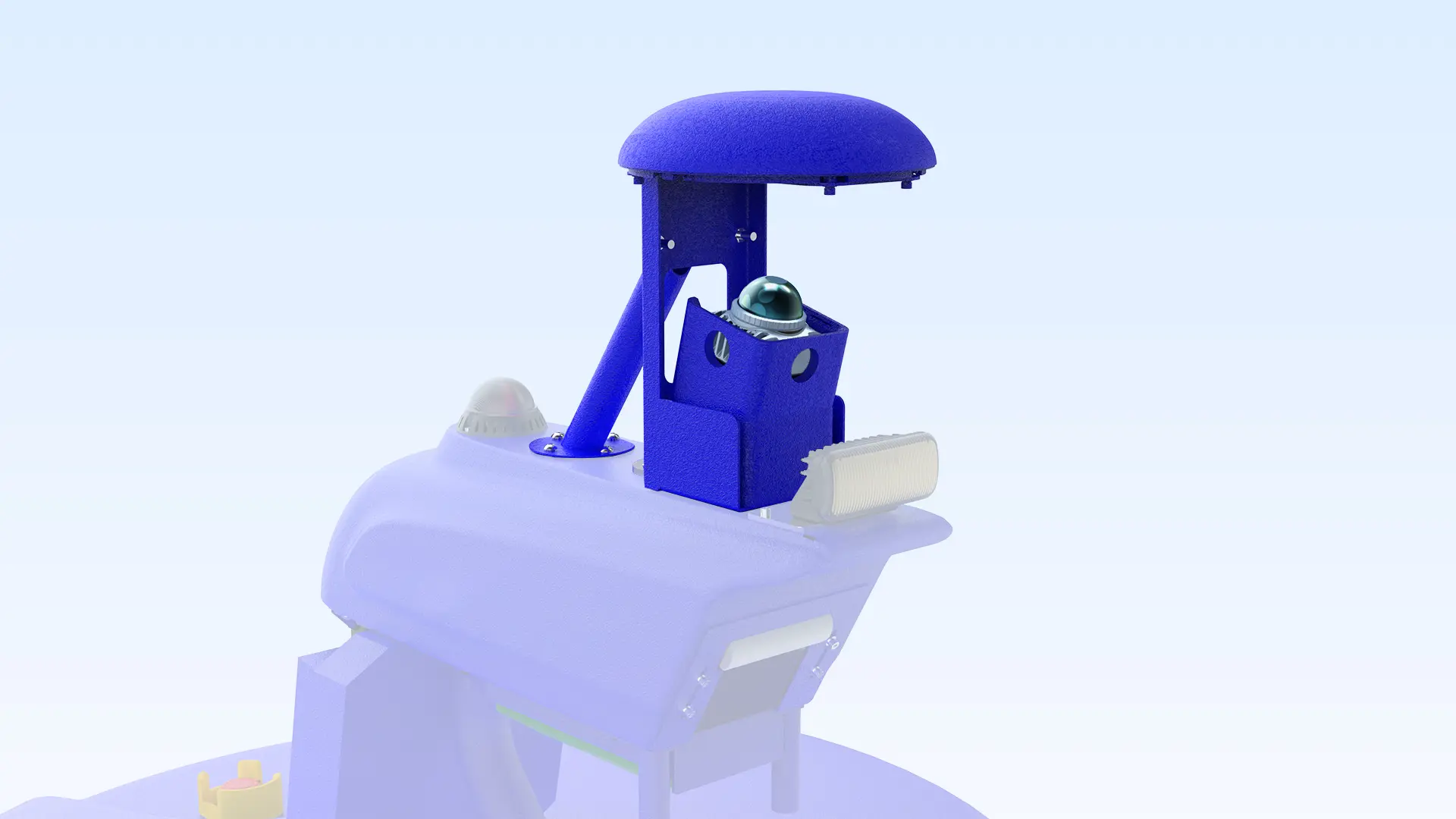

3D Kit: Upgrade your Nimbo to Nimbo X!

Already own a Nimbo or Nimbo Plus? No problem. Upgrade with our 3D Kit to transform your current model into a LiDAR-powered smart feed pusher — bringing all the benefits of Nimbo X without needing a full replacement.

3D Kit: Upgrade your Nimbo to Nimbo X!

Already own a Nimbo or Nimbo Plus? No problem. Upgrade with our 3D Kit to transform your current model into a LiDAR-powered smart feed pusher — bringing all the benefits of Nimbo X without needing a full replacement.

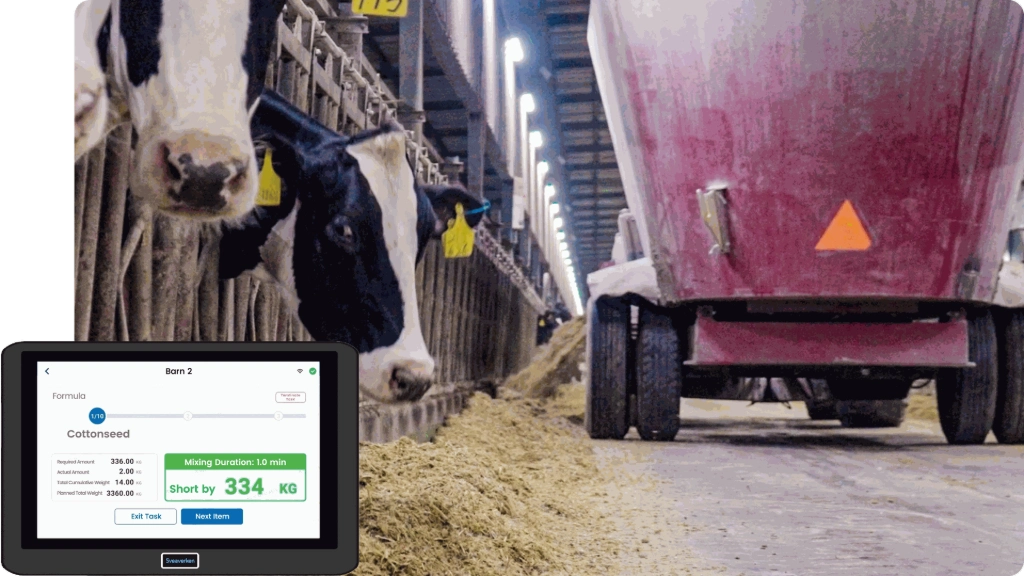

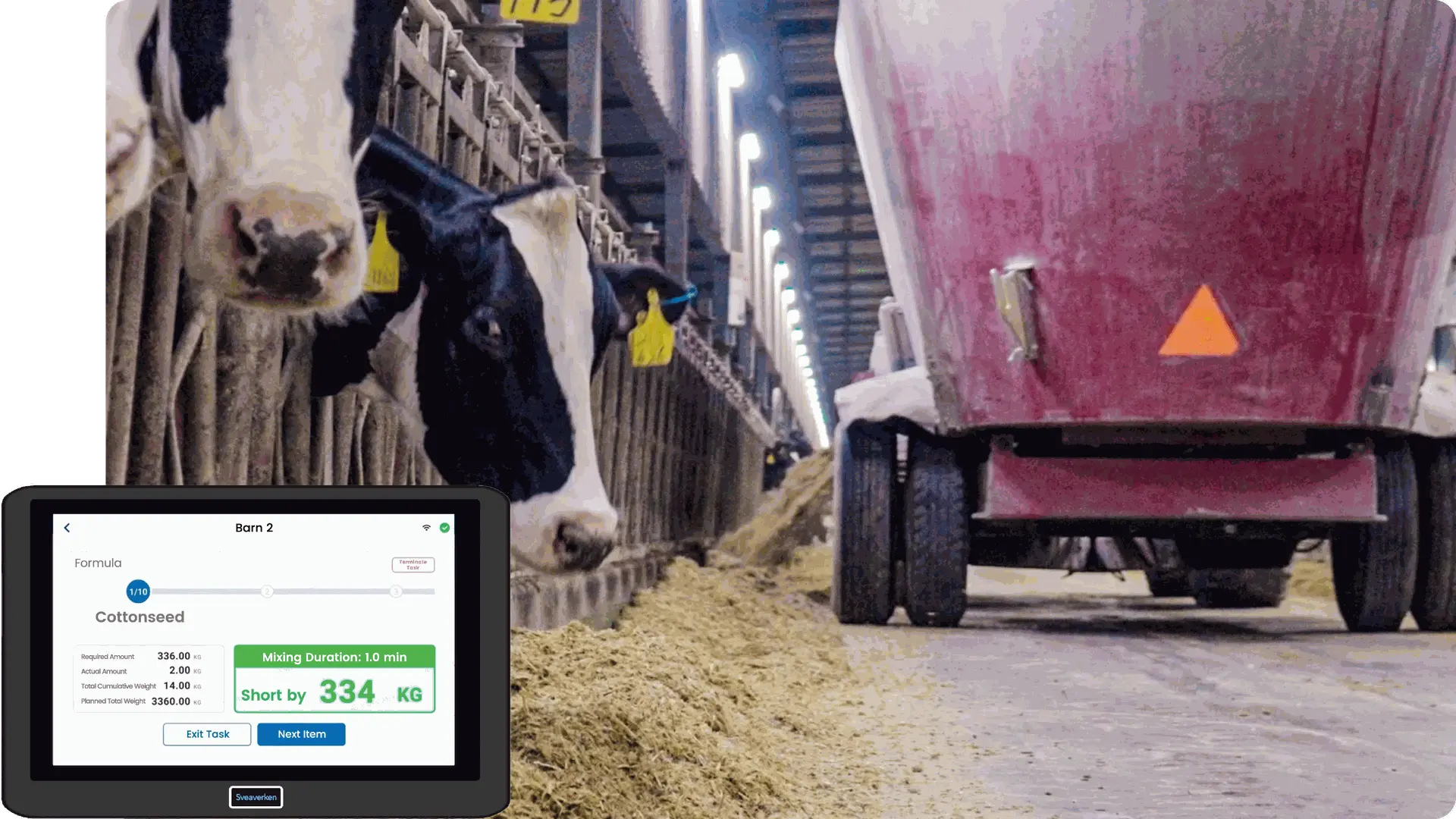

Nimbo X + TMR Optimization Kit:

Boost Milk Yield and Cut Feed Waste

Take the guesswork out of feeding! With Nimbo X and our TMR Optimization Kit, feeding your cows has never been easier.

Nimbo X uses smart camera algorithms to scan and track leftover feed, giving you real-time reports directly on MooConnect web. This feature is activated with the TMR Optimization Kit, ensuring you’ll always know exactly what’s left and what’s needed — cutting down on waste and improving feed management.

The TMR Optimization Kit takes it a step further, controlling Nimbo X and adjusting feed pushing times to avoid any overlap with the mixer wagon. With this powerful combo, optimize your feeding strategy, reduce waste, and increase milk yield. Feed your cows smarter, not harder.

GET THE MOST OUT OF YOUR INVESTMENT

GET THE MOST OUT OF YOUR INVESTMENT

Nimbo X is a true breakthrough in dairy farm automation. By combining 3D LiDAR and AI-powered vision, our robotic feed pusher can replace the work of up to three workers and a tractor, slashing labor hours and operational costs.

With lightning-fast installation, minimal upkeep, and pinpoint-accurate feed delivery, Nimbo X offers a cost-effective solution for farms of any size. Whether you're running a small operation or a large dairy, this smart feed pusher delivers long-term ROI through higher efficiency and reduced manual workload.

Ready to bring automation to your barn? Contact the Sveaverken team today and discover how the Nimbo X feed pusher robot can revolutionize your farm.